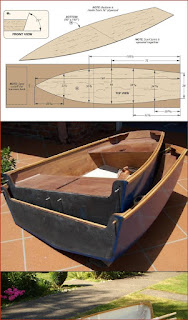

Free Plywood Dinghy Plans: Your Guide to Building Your Own Boat

Hey there, fellow DIY enthusiasts! So you're dreaming of building your own boat, huh? That's awesome! There's something incredibly satisfying about crafting something with your own two hands, especially something as cool as a plywood dinghy. And the best part? It doesn't have to break the bank. This guide will walk you through finding free plywood dinghy plans and building your own little watercraft. Get ready to get your hands dirty (and maybe a little wet!).Why Choose a Plywood Dinghy?

Plywood is a fantastic material for boatbuilding, especially for beginners. It's relatively inexpensive, readily available at most home improvement stores, and surprisingly strong when used correctly. Plus, the construction process is generally easier than using fiberglass or other more complex materials. A plywood dinghy is perfect for:

- Exploring calm waters: Think lakes, bays, and slow-moving rivers.

- Fishing: A stable platform for a quiet afternoon of angling.

- Tendering: Perfect for getting from a larger vessel to shore.

- Recreational use: Just a fun way to get out on the water!

Remember though, a plywood dinghy is generally not suitable for rough seas or high speeds. It's designed for calm waters and leisurely use.

Finding Free Plywood Dinghy Plans Online

The internet is a goldmine of information, including free boat plans! However, sifting through the plethora of websites can be overwhelming. Here's what to look for and where to start your search:

Reliable Sources for Boat Plans:

Don't just grab the first plan you see! Check the source's reputation. Look for sites with detailed instructions, clear diagrams, and positive reviews from other builders. Some places to start your search include:

- Boatbuilding forums and communities: These online communities often have members who share their plans and offer advice.

- Websites dedicated to boatbuilding: Many websites specialize in providing boat plans, some offering free options.

- YouTube tutorials: While not always providing complete plans, many YouTubers demonstrate the building process of plywood dinghies, offering valuable insights.

- Classic boat plans websites: Sometimes, you can find older, free plans that are still perfectly suitable for building a simple dinghy.

What to Look For in a Good Set of Plans:

Before you start downloading, make sure the plans are comprehensive and easy to understand. Here's a checklist:

- Detailed material list: This should specify the type and quantity of plywood, hardware, and other materials you'll need.

- Clear diagrams and drawings: The plans should have easily understandable diagrams showing the shape and dimensions of each part of the boat.

- Step-by-step instructions: The instructions should be clear and concise, leading you through the building process logically.

- Specifications and dimensions: The plans should include the overall length, beam (width), and depth of the dinghy.

- Recommended plywood thickness: This is crucial for the strength and durability of your boat.

Essential Tools and Materials

Once you've found your plans, gather your materials. This is where careful planning pays off. Having everything on hand will make the building process much smoother.

Tools You'll Need:

- Circular saw or jigsaw: For cutting the plywood sheets.

- Drill and drill bits: For drilling pilot holes and attaching parts.

- Screwdriver (or impact driver): For fastening screws.

- Clamps: Many, many clamps! You'll need these to hold the pieces together while the glue dries.

- Measuring tape and square: Accurate measurements are crucial.

- Sandpaper and sanding block: For smoothing out surfaces.

- Safety glasses and hearing protection: Always prioritize safety!

Materials You'll Need:

The specific materials will depend on your chosen plans, but generally you'll need:

- Marine-grade plywood: This is essential! Standard plywood will rot quickly in the water.

- Epoxy resin and hardener: For sealing the plywood and adding strength.

- Wood screws: Use stainless steel or bronze screws to prevent rust.

- Wood glue: A good quality waterproof wood glue is a must.

- Paint or varnish: To protect the plywood from the elements.

- Hardware for oars or a motor (if applicable): Choose the right hardware based on your dinghy design.

Building Your Dinghy: A Step-by-Step Overview

Building a plywood dinghy takes time and patience. Each plan will have its own instructions, but generally the process involves these steps:

- Cutting the plywood: Carefully cut the plywood pieces according to the plans, paying close attention to accuracy.

- Assembling the hull: This often involves joining the bottom and sides of the boat, using glue and screws. Clamps are your best friend here!

- Adding reinforcements: Many plans call for reinforcing the hull with additional pieces of plywood or fiberglass cloth.

- Sealing and finishing: Once assembled, seal all joints and surfaces with epoxy resin to make the boat waterproof.

- Painting or varnishing: Protect your beautiful creation with a durable paint or varnish.

- Adding hardware: Install any necessary hardware, such as oarlocks or a motor mount.

Remember, take your time, follow the plans meticulously, and don't be afraid to ask for help if you get stuck. There are many online communities dedicated to boatbuilding where you can find advice and support.

Commonly Asked Questions

Here are some frequently asked questions about building plywood dinghies:

- Q: What type of plywood should I use? A: Always use marine-grade plywood. It's specifically designed to resist rot and water damage.

- Q: How long does it take to build a plywood dinghy? A: This depends heavily on the size and complexity of the dinghy, as well as your experience level. It could take anywhere from a few weeks to several months.

- Q: Do I need any special skills? A: Basic woodworking skills are helpful, but it's not necessary to be a professional. Careful attention to detail and patience are more important.

- Q: Can I use a different type of adhesive? A: While some adhesives might work, epoxy resin and marine-grade wood glue are highly recommended for their waterproof properties.

- Q: How do I register my homemade boat? A: Registration requirements vary by location. Check with your local boating authorities for specific guidelines.

- Q: What if I make a mistake? A: Don't worry! Mistakes happen. Take a deep breath, assess the situation, and see if you can correct it. Sometimes, starting over on a small section is easier than trying to salvage a major error.

Happy building, and fair winds!